F23 Swap Guide

Out Now!

If you find this info useful and want to see more reference info added to the site, click the Patreon link above and tip me a couple bucks.

Torque Specs, Capacities, Intervals, etc

1996-00 Honda Civic

- Oil Change

- Oil Capacity D16Y7 3.8qt w/filter, 4.5qt overhaul

- Oil Capacity D16Y5, D16Y8 3.5qt w/filter, 3.9qt overhaul

- Oil Capacity B16A2 4.2qt w/filter, 5.1qt overhaul

- Oil Change Interval 7500 miles / 12 months, Filter 15k miles or 12 months

- 5w30 best fuel economy all climates, 10w30 climates above 20F

- Oil Pressure @ Idle (minimum) 9kPa, 10psi

- Oil Pressure @ 3000RPM (minimum) 340kPa, 50psi

- Oil Filter 16 ft/lbs

- Oil Drain bolt 33 ft/lbs

- Oil Pan mount nut/bolt 8.7 ft/lbs (104 in/lbs) (three steps, criss-cross pattern)

- Oil Pickup 8 ft/lbs (86 in/lbs)

- Oil Pump small bolts 8 ft/lbs (86 in/lbs) large bolts 17 ft/lbs

- Oil Pump Sealing bolt 29 ft/lbs

- Oil Pressure Switch 13 ft/lbs (156 in/lbs)

- Transmission, Rear Main Seal

- Fluid Change Interval 90k miles 6 years, CVT 15k miles 2 years

- Fluid Capacity M/T S40 (D Series) 1.9qt, 2qt overhaul, Honda MTF

- Fluid Capacity M/T S4C (B16A2) 2.3qt, 2.4qt overhaul, Honda MTF

- Fluid Capacity A/T 2.9qt, 6.2qt overhaul, Honda ATF

- Fluid Capacity CVT 4.1qt, 6.8qt overhaul, Honda CVT Fluid

- Pressure Plate 19 ft/lbs

- Flywheel 87 ft/lbs (criss-cross sequence)

- Flex Plate (Automatic) 54 ft/lbs

- Rear Main Seal Cover 8 ft/lbs (86 in/lbs)

- Clutch Master Cylinder 9 ft/lbs (108 in/lbs)

- Clutch Slave Cylinder 16 ft/lbs

- Transmission Mounting Bolts 47 ft/lbs

- Starter Bolts 33 ft/lbs

- Transmission Oil Filler bolt 33 ft/lbs

- Transmission Drain bolt 29 ft/lbs

- Bitch Pin Punch Size 8mm

- Intermediate Shaft 29 ft/lbs

- Axles, Wheel Bearings, Ball Joints

- Tie Rod nut 29-35 ft/lbs

- Upper Ball Joint 29 - 35 ft/lbs

- Lower Ball Joint 36 - 43 ft/lbs

- Shock Fork Pinch bolt 32 ft/lbs

- Shock Fork Lower bolt 47 ft/lbs

- Axle nut 134 ft/lbs

- Wheel Alignment check 15k miles yearly

- Brakes

- Brake Fluid Change Interval 30k miles 2 years

- Caliper Bleed Screw (78 in/lbs)

- Drum Bleed Screw (60 in/lbs)

- Wheel Cylinder (78 in/lbs)

-

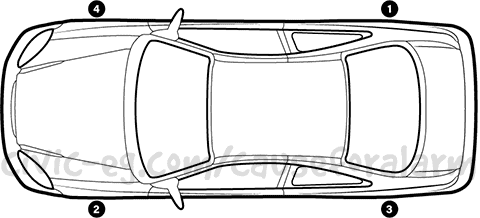

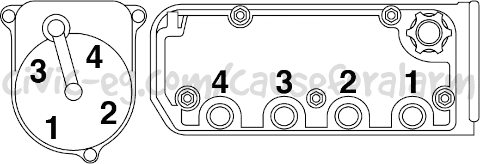

- Bleed Sequence

- Rear Right

- Front Left

- Rear Left

- Front Right

- Lug nuts 80 ft/lbs

- Brake Disc Screws 7 ft/lbs (84 in/lbs)

- Parking Brake Lever 6-10 clicks

- Brake Hose Banjo bolt 25 ft/lbs

- Caliper bolts Front (non ABS) 20 ft/lbs

- Caliper bolts Front (ABS) 24 ft/lbs

- Caliper Bracket Front 80 ft/lbs

- Caliper bolts Rear 17 ft/lbs

- Caliper Bracket Rear 28 ft/lbs

- Brake Master Cylinder 11 ft/lbs (132 in/lbs)

- ABS Sensor (84 in/lbs)

- Intake

- Intake Manifold nuts 17 ft/lbs

- Throttle Body 16 ft/lbs

- IACV 16 ft/lbs

- Air Filter Change Interval 30k miles or 24 months (clean yearly)

- EGR clean D16Y5 60k miles 4 years

- EGR nuts 15 ft/lbs

- Exhaust

- Exhaust Manifold nuts 23 ft/lbs

- Heat Shield 17 ft/lbs

- Manifold Support Bracket 33 ft/lbs

- O2 Sensor 33 ft/lbs

- Exhaust Spring bolts 16 ft/lbs

- Downpipe to B Pipe 40 ft/lbs

- Downpipe Support to Block 17 ft/lbs, to Pipe 12 ft/lbs (144 in/lbs)

- B Pipe 25 ft/lbs

- Coolant

- Coolant Flush Interval 45k miles 3 years

- Drain Bolt 58 ft/lbs D series next to oil filter, B16A2 next to exhaust manifold

- Radiator Cap Pressure 93-123kPa 14-18psi

- Radiator Fan On Temperature 196-203F

- Coolant Bleed bolt 7 ft/lbs (86 in/lbs)

- Thermostat Housing 8 ft/lbs (96 in/lbs)

- Thermostat Starts Opening 169-176°F Fully Open 194°F

- Water Outlet Cover 8 ft/lbs (86 in/lbs)

-

- Engine Coolant Temperature Sensors

- ECT Switch (Radiator Fan) (2 pin on thermostat housing) 16-19 ft/lbs

- ECT Sending Unit (Dash Gauge) (1 pin under distributor) 7 ft/lbs (84 in/lbs)

- ECT Sensor (ECU Signal) (2 pin near water neck) 13 ft/lbs (156 in/lbs)

- Timing Belt, Water Pump

- Timing Belt Change Interval 90k miles 6 years

- Cover bolts 7 ft/lbs (84 in/lbs)

- Water Pump 9 ft/lbs (108 in/lbs), D Series large bolt 33 ft/lbs

- Crank Pulley bolt 14 ft/lbs + 90° turn, B16A2 130 ft/lbs

- Rotate Engine (counter-clockwise) 5-6 times, loosen Tensioner 1/2 turn, rotate engine 3 teeth, torque Tensioner

- Tension Pulley 33 ft/lbs, B16A2 40 ft/lbs

- Cam Pulleys D Series 27 ft/lbs, B16A2 41 ft/lbs

- CKF Sensor 9 ft/lbs (104 in/lbs)

- Fuel

- Fuel Octane D Series 86 or higher

- Fuel Octane B16A2 91 or higher

- Fuel Filter Change Interval 60k miles 4 years

- Fuel Rail Mounting nut 9 ft/lbs (108 in/lbs)

- Fuel Pressure Regulator 9 ft/lbs (108 in/lbs)

- Fuel Filter Service bolt 9 ft/lbs (108 in/lbs)

- Fuel Hose to Filter 25 ft/lbs

- Fuel Feed Line to Filter 28 ft/lbs

- Fuel Hose to Rail 16 ft/lbs

- Fuel Hose to Pump 21 ft/lbs

- Fuel Tank Capacity 11.9 gal

- Fuel Pump 222cc/min 7.5oz/min

- Fuel Pump Mounting nuts (52 in/lbs)

- Fuel Tank Drain bolt 36 ft/lbs

- Engine Running, Vacuum Hose Disconnected Fuel Pressure D Series 38-46psi, B16A2 40-47psi

- Vacuum Hose Connected Fuel Pressure 28-36psi, B16A2 30-37psi

- Fuel Injector Resistance 10-13 Ohm (Saturated)

- D16Y5 Fuel cut-off 6900RPM DFCO above 850RPM, CVT 920RPM

- D16Y8 Fuel cut-off 7000RPM DFCO above 920RPM A/T 910RPM

- D16Y7 Fuel cut-off 6900RPM DFCO above 910RPM A/T 910RPM

- B16A2 Fuel cut-off 8100RPM DFCO above 970RPM

- Idle

- IACV 16 ft/lbs

- Idle Speed IACV Unplugged 480 +/- 50

- Idle Speed check 60k miles 4 years

- Idle Speed 670RPM +/- 50, A/T 700RPM +/- 50, B16A2 700RPM +/- 50

- Fast Idle Speed +150-300RPM (1400-1800RPM) until 176F

- FITV 9 ft/lbs (108 in/lbs)

- TPS Voltage .5V idle - 4V WOT

- Throttle Cable Deflection 10-12mm

- O2 Sensor Heater 10-40 Ohm

- Cylinder Head

- Compression minimum 135psi, max variation 28psi

- Head bolts D Series step one 22 ft/lbs, step two 49 ft/lbs, From the center, out

- Head bolts B16A2 Install manifolds. Step one 22 ft/lbs, step two 61 ft/lbs, From the center, out.

- PCV check 60k miles 4 years

- Valve Cover nuts 7 ft/lbs (86 in/lbs)

- Valve Clearance check 30k miles only

-

- Valve Lash D Series

- Intake .007 - .009in .18 - .22mm

- Exhaust .009 - .011in .23 - .27mm

- Locking nuts (D16Y7) 156 in/lbs

- Locking nuts (D16Y5, D16Y8) 168 in/lbs

- mm Jam Nut Tool

- Valve Lash B16A2

- Intake .006 - .007in .15 - .19mm

- Exhaust .007 - .008in .17 - .23mm

- Locking nuts in/lbs

- mm Jam Nut Tool

- Ignition

- Ignition Timing check 60k miles 4 years

- Ignition Timing 12° +/- 2

- Coil Primary Resistance @68°F Hitachi .45 - .55 Ohm, TEC .63 - .77 Ohm

- Coil Secondary Resistance @68°F Hitachi 22.4 - 33.6 Ohm, TEC 12.8 - 19.2 Ohm

- Alternator 75-80A

- Spark Plug Change Interval 30k miles 2 years

- Spark Plug Gap 1 - 1.1mm .039 - .043"

- D16Y5 ZFR4F-11, D16Y7, D16Y8 ZFR5F-11

- Spark Plugs 13 ft/lbs (156 in/lbs)

- Distributor 17 ft/lbs

- Distributor Cap and Rotor Change Interval 60k miles 4 years

- Spark Plug Wires Inspection Interval 60k miles 4 years

- Air Conditioning

- Refrigerant Capacity 22.9oz +0 -1.8

- Lubricant Nippon Denso ND-OIL8 PAG 46, Sanden SP-10

- Tension new belt, run engine for 5 minutes, re tension

- Compressor bolts 18 ft/lbs

- Steering

- Fluid Capacity (Change) .9qt Honda-specific Fluid

- Tension new belt, run engine for 5 minutes, re tension

- Steering Ratio power 17.7, manual 20.3

- Turns Lock-to-Lock power 3.6, manual 4.1

- Steering Wheel diameter 15"

- Camber Front 0, Rear -1°

- Caster 1°4'

- Total Toe Front 1mm (1/16"), Rear 2mm (1/16")

- OBD1-OBD2 DTCs (Check engine light flashes)

- 0 - Engine Control Module

- 1 - Primary Heated Oxygen Sensor (HO2S)

- 3 - Manifold Absolute Pressure (MAP Sensor)

- 4 - Crankshaft Position (CKP Sensor)

- 5 - Manifold Absolute Pressure Signal High/Low

- 6 - Engine Coolant Temperature (ECT Sensor)

- 7 - Throttle Position (TPS) High/Low

- 8 - Top Dead Center Position (TDC Sensor)

- 9 - No. 1 Cylinder Position (CYP Sensor)

- 10 - Intake Air Temperature (IAT Sensor)

- 12 - Exhaust Gas Recirculation Insufficient Lift

- 13 - Barometric Pressure (BARO Sensor)

- 14 - Idle Air Control Valve (IACV)

- 15 - Ignition Output Signal

- 16 - Fuel Injector

- 17 - Vehicle Speed Sensor (VSS)

- 20 - Electrical Load Detector (ELD)

- 21 - VTEC Solenoid (VTS)

- 22 - VTEC Pressure Switch (VTP SW)

- 23 - Knock Sensor (KS)

- 30 - A/T FI Signal A

- 31 - A/T FI Signal B

- 41 - Primary Heated Oxygen Sensor Heater

- 43 - Fuel Supply System

- 45 - System Too Rich/Lean

- 48 - Primary Heater Oxygen Sensor Circuit

- 54 - Crankshaf Speed Fluctuation (CKF Sensor)

- 61 - Primary O2 Sensor Slow Response

- 63 - Secondary O2 Sensor

- 65 - Secondary O2 Sensor Heater

- 67 - Catalyst System Efficiency Below Threshold

- 70 - A/T FI Data Line

- 71 - Cylinder 1 Random Misfire

- 72 - Cylinder 2 Random Misfire

- 73 - Cylinder 3 Random Misfire

- 74 - Cylinder 4 Random Misfire

- 80 - Exhaust Gas Recirculation Insufficient Flow (EGR)

- 86 - Engine Coolant Temperature (ECT)

- 90 - Evaporative Emission Control System (EVAP)

- 91 - Fuel Tank Pressure Sensor

- 92 - Evap Emission Control Insufficient Purge Flow

Helm Inc, Civic Shop Manual, Part No. 62S0324, Honda Motor Co., LTD. Service Publication Office, 1999, pp. 1848

Recommended Tools

These are tools that I can't live without that may be overlooked by the average enthusiast. Clicking on these tools helps support Cause For Alarm and doesn't increase the cost to you (As an Amazon Associate I earn from qualifying purchases). For the few that aren't the exact brand I own, I've made a recommendation after carefully weighing cost against reliable reviews, using what I know to be important in that particular tool. I am not sponsored.

CLICK THE PICS TO SEE THE TOOL on Amazon

3/8" Cordless Impact

This thing is rarely leaves my hand, it might as well replace an arm. Using a 20 volt, brushless, 3/8" impact compared to ratcheting on stuff is a whole other ballgame. It makes this hobby so much more fun. And it will blow your mind what this relatively small, lightweight, battery powered impact can do. Great for when you're at the junkyard and the parts that normally stabilize your part are gone, and you need to apply lots of torque to something flopping in the air. Removing the steering wheel on a loose column comes to mind. Cracking lug nuts off when the wheels are in the air. Any suspension bolt is cake. I will often try it first on axle nuts and crank pulley bolts, because it so often impresses me. And if those are too stubborn, then I grab the 1/2" version.

Using an impact pretty much eliminates stripping bolts. You save yourself so much heartache on suspension and exhaust bolts. Not to mention busting your knuckles open pushing on a ratchet when it suddenly gives way. It's a huge time saver over the course of a big project. You'll save hours on an engine or suspension swap, and you wont be all beat up and worn out afterward.

For years I ratcheted on things and thought I enjoyed it. I would sometimes switch to an electric drill with a socket adapter to zip bolts off after breaking them loose. I broke ratchets routinely 2-3 times per year. My hands were always cut and sometimes bruised. I had a pneumatic impact, but it was inconvenient to drag the compressor out and then irritating to listen to and wait for it to pressure up, only to drone on again after only a couple uses. Being attached to a hose SUCKS. I didn't use it in the evening hours out of consideration for the neighbors. It disappointed me often. The air equipment you're likely to have at home often isn't strong enough and you end up resorting to a breaker bar.

If you do your own maintenance, get this. If you're looking for a gift idea for a weekend mechanic, this is it. I regret not getting it sooner and thinking it wasn't a justified purchase. But for how often I use it, how much I enjoy it, and all the benefits to it, it's well worth it.

This is the entire kit if you don't already have any DeWalt 20v tools.

So just to be clear: get yourself the 3/8" Impact TODAY. Get the 1/2" on your next birthday.

1/2" Cordless Impact

This is the 1/2" Impact. It's too bulky to use on everything, but this is your lifesaver when bolts are stuck. This will zip off crank pulley bolts without much fuss and no need for a crank holder tool. It will zip off axle nuts without having to unstake them. Get one before you do an engine swap or any major suspension project.

The 1/2" Impact kit comes with a larger capacity battery than what comes in the 3/8" impact kit, but the smaller battery can be used interchangeably. The chargers are different. Battery size affects how long you can use the tool before charging, but the power output of the tool is the same either way. The 1/2" balances better in your hand with the bigger battery. So getting the 3/8" and 1/2" Impact kits is preferred. For max cost savings, you could get the 1/2" impact kit and the 3/8" bare tool. When you go to get the drill, reciprocating saw, jig saw, you can get them as bare tools.

The light kits are handy to be able to throw a battery on and get light, but they're not particularly wonderful to use. If you got money and can get a good deal on the accessory kit (as I did), then go for it. Otherwise there are better options for light.

Torque Wrench

This is a cheap but excellent quality 3/8" torque wrench. It goes from 10-80 ft/lbs which covers just about everything. For anything with a spec calling for over 80 ft/lbs (and isn't internal to the engine), I trust the 1/2" impact.

You should absolutely be using a torque wrench on lug nuts, brake jobs, valve cover bolts, and spark plugs. I used one on everything in my early years of this hobby and I consider it training. I still use it frequently on sensitive, critical and recommended things.

It's metal for durability, easy to clean, easy to use. And it's accurate compared to other torque wrenches I've tested it against.

Mini Sledge

It will surprise you how often you need this simple tool, and how many times it gets you out of a jam. Besides pairing it with a cold chisel, you can also use it like a manual impact with 2-3 sharp hits on a ratchet handle (for when the head of an impact gun wont fit). You also use it (WITH SAFETY GLASSES) to knock loose brake drums (make sure you released the parking brake) or even carefully tapping off stuck wheels or brake discs.

Cold Chisel

Essential tool for easily separating lower ball joints and inboard axle joints. My son struggled for hours on each of these applications. With the chisel he gets through it instantaneously and without causing damage.

Safety Glasses

This is not the point where I harp on you about safety. This is where I remind you that it sucks any time you go under the car and you get dust or some liquid dripping in your eye. Your gloves are greasy, so you end up rolling around under there like a fish on land. And I have this story about getting a rust flake drilled out of my eye. Yes, the doctor used a drill bit in my eye. Yes, I got the rest of my work day off.

I used to use whatever glasses were readily available. Then I visited a mine for several days for a job, and they handed out these 3Ms like kittens. They're exactly what safety glasses should be. Hundreds of burly outdoor miners give their seal of approval.

Lifting Jack

I've gone through many jacks, from vintage heavy steel floor jacks to lightweight, low profile, aluminum, cheapy HF jacks. This is my all time favorite, and it's cheap!

It's part steel, part aluminum. Relatively lightweight and not too bad for lugging short distances. Low enough profile for my use, and lifts high enough as well. Pretty quick to pump up without too much effort. It's perfectly sized for Japanese cars. Lifts my CRV high enough if you know where the jack points are, but if your only vehicles are CRVs or trucks, look into getting the higher lifting version.

Don't get the Pittsburg that Amazon recommends. It's a HF brand I had years ago, and it failed on me.

Pancake Air Compressor

The size of the air compressor tank doesn't affect the power it generates. The pressure is the power, the size is the capacity, or how long you can use it. If you are concerned about power and capacity, you need a true industrial compressor. Don't make the mistake and lug around a big electric compressor like I once did. I couldn't paint with and that wasn't powerful enough to make an impact gun useful.

Deciding to trade in my bulky air compressor for something convenient and practical was a no-brainer. Sweating over mixed reviews of a few dozen brands caused weeks of procrastination. I finally pulled the trigger on this one and I couldn't be happier.

The sound is relatively muffled. MUCH more tolerable than the big Craftsman I had for the longest time. The capacity is obviously much less, but it's fine for the jobs I use it for. Inflating tires, dusting out electronics and consoles, occassionally using an air hammer or die grinder. Everyone needs one, get it!

T Handle Bit Driver

A cheap yet essential tool. You need this so you don't strip disc brake retaining screws, MAP sensor screws, glove box mount screws. The shape of it allows you to apply downward pressure. I have a HF brand with the extension seized inside. After looking through the Amazon offerings and their reviews, this is the one I recommend.

Bit Driver Set

You also need a bit driver set. It should contain a wide range of Torx bits, preferably the security type. It obviously needs P0-2. I never use PZ or Hex and would rather they weren't in the set. 6mm, 8mm, 10mm, 12mm nut drivers would be nice.

I like my bit driver set but could not find anything comparable or even recommendable on Amazon, sorry.

Angle Driver

A genius tool. Can be awkward to use, but you'll love life when you need it and you have it. It's for the times when you can't get a screwdriver in front of a screw.

Electric Screwdriver

You can't be taken seriously as a Car Audio Tech without a small, torquey electric screwdriver. A lovely tool for stripping out interior for stealth alarm installs and also has many uses around the house. It pairs nicely with the same bit drivers you'll be using with the T Handle tool. My wife loved using it. I loved my wife. This is the past tense. Moving on...

I have an old Snap On and a Metabo kit, but today you have better and much more affordable options. This is the one to get.

3/8" Ratchet

You already have a ratchet, but you can get this one after you break it. It's fine tooth and nice overall. I'm happy with Tekton brand sockets etc.

10mm Flare Nut Wrench

It's at your peril if you don't get one of these for Honda brake lines. The wrench looks flimsy, but I like that it has 8mm and 10mm for bleeder screws. On the Crow's Foot, you insert the ratchet into the square, giving you more angles to work with removing the proportioning valve up against the firewall. These are some options - I honestly have a Craftsman and my son has an overpriced one he had to get from AutoZone in desperation. It's weak steel but it works.

10mm / 12mm Double Offset Box Wrench

A tool dear to my heart for the pain and suffering it has saved me. The length of it also provides good leverage for torque. I have a Craftsman and love it. The Craftsman brand is dirt, but acceptable for wrenches, ratchets and sockets. I was unsure about the no-name brands available on Amazon and don't want to risk recommending one without having tried it.

Ratcheting Wrenches

My brother got me a metric Gear Wrench set and I've been abusing them for decades. It's time for a new set but I'm not yet satisfied there isn't a cheaper option.

Rotary Tool

There are so many times I need to grind or cut a plastic or metal part to make something custom or make a repair, that I would put this on the list of tools you should plan to get. It's not used frequently, but it's an absolute life saver to have when you're in a bind.

I've had my Dremel for over a decade, but the lowest speed died on it almost immediately. It's been reliable besides that, but for the cost, I looked for what I would take a chance on if I had to replace it.

Multimeter

Spend an hour getting comfortable with testing 12v DC and continuity. Open up an entire specialty of possibilities. Become the envy of all your friends.

Solder Gun

Get it, get comfortable using it. Stop treating wiring like black magic. It's cake.

Crimpers

I swear by the Channel Lock 909s that I've used for two decades, but I posted a promising-looking cheaper alternative as well.

Crimping non-insulated butt connectors with heat shrink is preferred in some instances. Especially 10awg or thicker. It's bulkier, but arguably superior to soldering. You need crimpers for ring terminals, and these are good for cutting 16~10awg wire.

The flat side of the butt connector is inserted up against the protrusion on the crimpers, with the seam opposite of it. After crimping, turn the butt connector on it's side and crush it in the crimpers again to close the indentation together like you see on OEM crimps. Then heat shrink it and forget it.

Heat Gun

Switch to using heat shrink because insulated butt connectors are bulky, amateurish junk. Also for applying double-sided tape and removing tint.

Side Cutters

Pricey but justified. Knipex is the best. Essential for serious wiring work. You could get away with just the Crimpers and Wire Strippers if you're never planning to touch wires again. For a single alarm install I urge you to get a cheap set of Side Cutters at a bare minimum, but I wont recommend a crap product here.

Wire Insulation Strippers

These are nice to have and any cheap set will do, but you should practice using side cutters to strip wire insulation also.

Panel Poppers

Essential for removing interior pieces. Stop scarring and breaking your plastic.